Smart software at EMO Hannover

Frankfurt am Main, 03. september 2019. – Relieving engineers of tiresome routines and unleashing their creativity: the goal of AMendate GmbH from Paderborn is to take additive manufacturing to the next level. The new company is planning to have its latest piece of software ready for market in time for the EMO Hannover trade fair where it will be presenting its innovation on the joint start-up stand. The aim of the young entrepreneurs is to raise the company’s profile and then rapidly dominate the market for generative design.

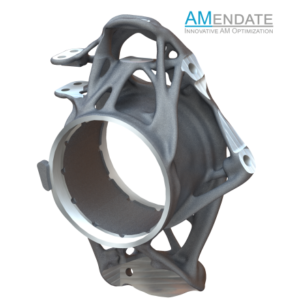

It all started with four friends who, during more than four years of research at the Research Center for Additive Manufacturing (DMRC) of the University of Paderborn, came to an important realisation: industrial 3D printing offered many different possibilities for producing delicate but highly robust light metal components at low cost, yet there was a lack of suitable software. Manual data transfer into CAD formats was time-consuming and labour-intensive and left a lot of room for interpretation. This led in turn to a loss of quality. “Our aim was to solve this problem,” says Dr. Thomas Reiher, who explored the generation of complex bionic structures as part of his dissertation and is now a managing director of the founding team of AMendate GmbH. For over four years now he has been developing a piece of technology that automates and interprets the process of data transmission and intelligently smoothes the resulting geometric data. This led to the establishment of a company dedicated to making the technology more user-friendly.

More time for value-adding instead of manual data transfer

The result is software that increases the quality of additively manufactured components and considerably speeds up the processes. After being given a final polish, its market launch is scheduled for the summer. Reiher: “Our software ensures that geometries are no longer unintentionally removed during data smoothing. Furthermore, the technology allows work steps to be completed in days that would otherwise take several weeks.

Fears that automation might make skilled staff superfluous are resolutely countered by the young entrepreneurs. Dr. Gereon Deppe, a co-founder of the start-up and responsible for marketing and finance, believes that, on the contrary, their role in value creation will gain in importance: “Instead of getting bogged down in the minutiae of data processing, engineers can devote much more attention to the creative process. This gives them time to optimise the basic concept of the product and to integrate additional features.”

Industry has already realised that this approach has the potential to revolutionise additive manufacturing. Readers of the industry portal 3Dnatives voted AMendate the most innovative start-up of 2018 in an international poll. The company was also able to land Exist start-up scholarships for three of its employees. In addition it has entered into a close partnership with Protiq GmbH from Blomberg, an established additive manufacturer. Based on AMendate’s technology, Protiq is now the first service provider worldwide to offer online topology optimisation that creates added value through its user-friendliness.

Wide range of applications for lightweight components

According to its founders, the company’s approach will turn additive manufacturing from a promising technology into a key technology. Reiher: “There is great demand for delicate lightweight design — especially for the production of small numbers of special machines — in many areas from the aviation and automotive industries through to mechanical and plant engineering. We offer a costeffective tool that generates components for immediate use and reduces material quantities.” The focus is not only on working for established customers to redesign classic product components in a way which permits additive manufacture, but also on creating entirely new components using a 3D printer.

Boosting growth as market leader

The team is currently working on an intuitive user interface that allows components to be optimised without the need for extensive prior knowledge and thus enables smaller companies to use additive manufacturing in their production. Deppe: “Our goal is to be instrumental in shaping the generative design market. Our vision is to be able to optimise all components in the future. This will help reduce raw material consumption levels and promote sustainable production.” To make this vision a reality, AMendate has set its sights on achieving rapid national and international growth based on its technology leadership. The market is currently relatively small, but Deppe is convinced that it provides a good basis: “It is still very difficult for customers to find providers with the necessary experience, competence or suitable offerings. This is where we come in: we can shape the market ourselves and actively drive processes forward.”

EMO Hannover – A platform for customer acquisition

EMO Hannover will be useful here. The start-up is counting on the international profile of the world’s leading metalworking trade fair and is hoping to make contact with new customers and interested parties from the key industries and sales markets. “It’s a great feeling to talk to experts and discover that your idea is being well received. Trade fairs help us to learn and to gain a clearer view of what the market needs,” says Reiher, who will be at EMO Hannover with his team shortly before the company’s first birthday. The theme of the fair – Smart technologies driving tomorrow’s production! – is also ideal for the young company, says Deppe enthusiastically: “We are digitalising a manual process that can then be supported by artificial intelligence and take place autonomously in the future. This makes us an enabler of additive manufacturing in the mass market, a real driving force behind the production of the future.”

Author: Stefan Schwaneck, VDW

Size: 6,000 characters including blanks